The manufacturing process continually evolves, driving growth and innovation for businesses worldwide. Each year brings new advancements, and industry giants such as stainless steel tanks manufacturers are at the forefront, taking advantage of cutting-edge solutions to optimize operations and stay competitive.

Check out the three transformative manufacturing solutions that shape the industry of giants in the field.

1. Industry Cloud Platform

Industry cloud platforms are specialized cloud computing platforms designed to meet the specific needs and requirements of particular industries. They offer industry-specific features, tools, and services designed to address the unique challenges and demands of sectors such as healthcare, finance, manufacturing, retail, and more.

The platforms provide a comprehensive suite of software applications, development tools, and infrastructure services optimized for industry-specific workflows and regulatory compliance.

Here are three cloud platforms:

- Salesforce Industry Cloud

- Microsoft Azure Industry Cloud

- SAP Industry Cloud

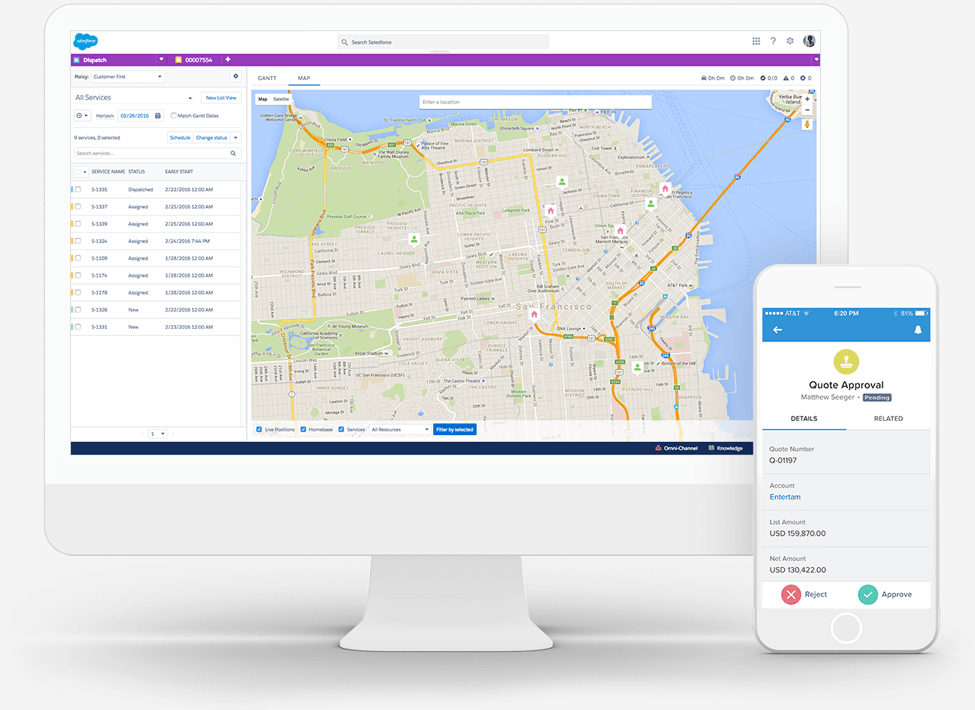

1. Salesforce Industry Cloud

Salesforce Manufacturing Cloud is a tailor-made CRM solution designed to unify customer-centric operations across the manufacturing lifecycle. It integrates sales agreements, account-based forecasting, and operations to improve demand forecasting and enhance visibility across the business ecosystem.

Key Features

- Advanced Forecasting: Provides precise operational forecasts, enabling strategic planning by combining sales agreements and opportunities for better demand prediction.

- Service Automation: Orchestrates end-to-end processes for customer support, complaints, and product issues, enhancing service efficiency and customer satisfaction

2. Microsoft Cloud Manufacturing

Microsoft Cloud for Manufacturing offers an integrated suite of tools designed to support the manufacturing sector by enhancing operational efficiency, driving innovation, and improving customer engagement through advanced analytics and cloud computing solutions.

Key Features

- Connected Factory: Integrates IoT and edge devices to monitor and optimize factory operations in real time, ensuring higher efficiency and reduced downtime.

- Supply Chain Visibility: Provides end-to-end supply chain insights with predictive analytics to anticipate disruptions and optimize logistics.

- Employee Empowerment: Utilizes collaboration tools like Microsoft Teams and Dynamics 365 to enhance workforce productivity and facilitate better communication and coordination across the organization

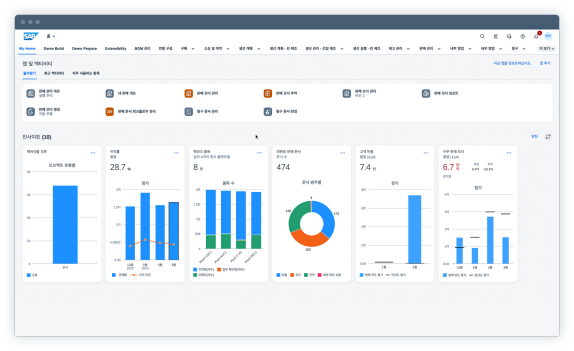

3. SAP Industry Cloud

SAP Digital Manufacturing Cloud is a comprehensive solution that connects production processes with business operations to enhance visibility, increase efficiency, and support real-time decision-making in the manufacturing sector.

Key Features

- Production Orchestration: Streamlines manufacturing operations by integrating planning and execution processes, allowing real-time visibility and control over production.

- Predictive Quality Management: Uses advanced analytics to predict and prevent quality issues, ensuring high standards and reducing waste.

- IoT Integration: Connects IoT devices and sensors to monitor equipment and production processes, providing real-time data and insights to optimize performance

2. Generative AI

Generative AI, a subset of artificial intelligence (AI), is revolutionizing the manufacturing industry by offering innovative solutions for design, optimization, and production. The algorithms are trained on vast datasets and can autonomously generate new designs, models, and solutions based on specified constraints and objectives.

Here’s how generative AI is shaping the manufacturing industry:

- Product Design and Optimization: By inputting parameters such as material properties, manufacturing constraints, and performance requirements, generative AI algorithms can quickly generate design alternatives that meet specific criteria.

- Manufacturing Process Optimization: Generative AI algorithms can optimize manufacturing processes by analyzing production data, identifying inefficiencies, and recommending improvements.

For example, in additive manufacturing (3D printing), generative AI can optimize support structures, reduce material usage, and minimize build time while ensuring part quality and performance.

- Supply Chain Management: Generative AI can optimize supply chain operations by analyzing demand forecasts, inventory levels, and supplier performance data to optimize procurement, production planning, and logistics.

3. Composable Hyperautomation

Composable hyperautomation is a transformative approach that combines various automation technologies to streamline and optimize business processes.

In the manufacturing industry, composable hyper automation is revolutionizing operations by enabling seamless integration of robotic process automation (RPA), artificial intelligence (AI), machine learning (ML), and other automation tools.

These are the hyper automation works:

- Process Efficiency and Optimization: Composable hyperautomation allows manufacturers to automate repetitive and manual tasks across the production process, from supply chain management to quality control.

- Predictive Maintenance and Asset Management: Composable hyperautomation enables predictive maintenance and asset management by combining IoT sensors, AI, and ML algorithms to monitor equipment health and performance in real-time.

- Supply Chain Optimization: Composable hyperautomation optimizes supply chain operations by automating procurement, inventory management, and logistics processes.

Conclusion

The three cutting edge solutions – industry cloud platform, generative AI, and hyper automation – are reshaping manufacturing for industry giants and driving efficiency and innovation.

Try out these manufacturing solutions to unlock new levels of productivity and competitiveness in your operations.